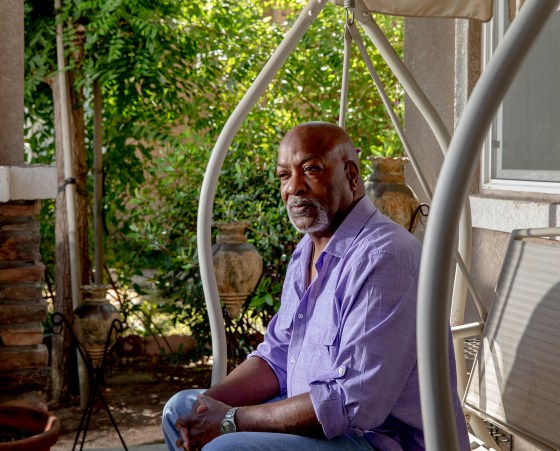

For 23 years, Larry Collins worked in a booth on the Carquinez Bridge in the San Francisco Bay Area, collecting tolls. The fare changed over time, from a few bucks to $6, but the basics of the job stayed the same: Collins would make change, answer questions, give directions and greet commuters. “Sometimes, you’re the first person that people see in the morning,” says Collins, “and that human interaction can spark a lot of conversation.”

But one day in mid-March, as confirmed cases of the coronavirus were skyrocketing, Collins’ supervisor called and told him not to come into work the next day. The tollbooths were closing to protect the health of drivers and of toll collectors. Going forward, drivers would pay bridge tolls automatically via FasTrak tags mounted on their windshields or would receive bills sent to the address linked to their license plate. Collins’ job was disappearing, as were the jobs of around 185 other toll collectors at bridges in Northern California, all to be replaced by technology.

Machines have made jobs obsolete for centuries. The spinning jenny replaced weavers, buttons displaced elevator operators, and the Internet drove travel agencies out of business. One study estimates that about 400,000 jobs were lost to automation in U.S. factories from 1990 to 2007. But the drive to replace humans with machinery is accelerating as companies struggle to avoid workplace infections of COVID-19 and to keep operating costs low. The U.S. shed around 40 million jobs at the peak of the pandemic, and while some have come back, some will never return. One group of economists estimates that 42% of the jobs lost are gone forever.

This replacement of humans with machines may pick up more speed in coming months as companies move from survival mode to figuring out how to operate while the pandemic drags on. Robots could replace as many as 2 million more workers in manufacturing alone by 2025, according to a recent paper by economists at MIT and Boston University. “This pandemic has created a very strong incentive to automate the work of human beings,” says Daniel Susskind, a fellow in economics at Balliol College, University of Oxford, and the author of A World Without Work: Technology, Automation and How We Should Respond. “Machines don’t fall ill, they don’t need to isolate to protect peers, they don’t need to take time off work.”

As with so much of the pandemic, this new wave of automation will be harder on people of color like Collins, who is Black, and on low-wage workers. Many Black and Latino Americans are cashiers, food-service employees and customer-service representatives, which are among the 15 jobs most threatened by automation, according to McKinsey. Even before the pandemic, the global consulting company estimated that automation could displace 132,000 Black workers in the U.S. by 2030.

The deployment of robots as a response to the coronavirus was rapid. They were suddenly cleaning floors at airports and taking people’s temperatures. Hospitals and universities deployed Sally, a salad-making robot created by tech company Chowbotics, to replace dining-hall employees; malls and stadiums bought Knightscope security-guard robots to patrol empty real estate; companies that manufacture in-demand supplies like hospital beds and cotton swabs turned to industrial robot supplier Yaskawa America to help increase production.

Companies closed call centers employing human customer-service agents and turned to chatbots created by technology company LivePerson or to AI platform Watson Assistant. “I really think this is a new normal–the pandemic accelerated what was going to happen anyway,” says Rob Thomas, senior vice president of cloud and data platform at IBM, which deploys Watson. Roughly 100 new clients started using the software from March to June.

In theory, automation and artificial intelligence should free humans from dangerous or boring tasks so they can take on more intellectually stimulating assignments, making companies more productive and raising worker wages. And in the past, technology was deployed piecemeal, giving employees time to transition into new roles. Those who lost jobs could seek retraining, perhaps using severance pay or unemployment benefits to find work in another field. This time the change was abrupt as employers, worried about COVID-19 or under sudden lockdown orders, rushed to replace workers with machines or software. There was no time to retrain. Companies worried about their bottom line cut workers loose instead, and these workers were left on their own to find ways of mastering new skills. They found few options.

In the past, the U.S. responded to technological change by investing in education. When automation fundamentally changed farm jobs in the late 1800s and the 1900s, states expanded access to public schools. Access to college expanded after World War II with the GI Bill, which sent 7.8 million veterans to school from 1944 to 1956. But since then, U.S. investment in education has stalled, putting the burden on workers to pay for it themselves. And the idea of education in the U.S. still focuses on college for young workers rather than on retraining employees. The country spends 0.1% of GDP to help workers navigate job transitions, less than half what it spent 30 years ago.

“The real automation problem isn’t so much a robot apocalypse,” says Mark Muro, a senior fellow at the Brookings Institution. “It is business as usual of people needing to get retraining, and they really can’t get it in an accessible, efficient, well-informed, data-driven way.”

This means that tens of thousands of Americans who lost jobs during the pandemic may be unemployed for years or, in Collins’ case, for good. Though he has access to retraining funding through his union contract, “I’m too old to think about doing some other job,” says Collins, who is 63 and planning on taking early retirement. “I just want to go back to what I was doing.”

Check into a hotel today, and a mechanical butler designed by robotics company Savioke might roll down the hall to deliver towels and toothbrushes. (“No tip required,” Savioke notes on its website.) Robots have been deployed during the pandemic to meet guests at their rooms with newly disinfected keys. A bricklaying robot can lay more than 3,000 bricks in an eight-hour shift, up to 10 times what a human can do. Robots can plant seeds and harvest crops, separate breastbones and carcasses in slaughterhouses, pack pallets of food in processing facilities.

That doesn’t mean they’re taking everyone’s jobs. For centuries, humans from weavers to mill workers have worried that advances in technology would create a world without work, and that’s never proved true. ATMs did not immediately decrease the number of bank tellers, for instance. They actually led to more teller jobs as consumers, lured by the convenience of cash machines, began visiting banks more often. Banks opened more branches and hired tellers to handle tasks that are beyond the capacity of ATMs. Without technological advancement, much of the American workforce would be toiling away on farms, which accounted for 31% of U.S. jobs in 1910 and now account for less than 1%.

But in the past, when automation eliminated jobs, companies created new ones to meet their needs. Manufacturers that were able to produce more goods using machines, for example, needed clerks to ship the goods and marketers to reach additional customers.

Now, as automation lets companies do more with fewer people, successful companies don’t need as many workers. The most valuable company in the U.S. in 1964, AT&T, had 758,611 employees; the most valuable company today, Apple, has around 137,000 employees. Though today’s big companies make billions of dollars, they share that income with fewer employees, and more of their profit goes to shareholders. “Look at the business model of Google, Facebook, Netflix. They’re not in the business of creating new tasks for humans,” says Daron Acemoglu, an MIT economist who studies automation and jobs.

The U.S. government incentivizes companies to automate, he says, by giving tax breaks for buying machinery and software. A business that pays a worker $100 pays $30 in taxes, but a business that spends $100 on equipment pays about $3 in taxes, he notes. The 2017 Tax Cuts and Jobs Act lowered taxes on purchases so much that “you can actually make money buying equipment,” Acemoglu says.

In addition, artificial intelligence is becoming more adept at jobs that once were the purview of humans, making it harder for humans to stay ahead of machines. JPMorgan says it now has AI reviewing commercial-loan agreements, completing in seconds what used to take 360,000 hours of lawyers’ time over the course of a year. In May, amid plunging advertising revenue, Microsoft laid off dozens of journalists at MSN and its Microsoft News service, replacing them with AI that can scan and process content. Radio group iHeartMedia has laid off dozens of DJs to take advantage of its investments in technology and AI. I got help transcribing interviews for this story using Otter.ai, an AI-based transcription service. A few years ago, I might have paid $1 a minute for humans to do the same thing.

These advances make AI an easy choice for companies scrambling to cope during the pandemic. Municipalities that had to close their recycling facilities, where humans worked in close quarters, are using AI-assisted robots to sort through tons of plastic, paper and glass. AMP Robotics, the company that makes these robots, says inquiries from potential customers increased at least fivefold from March to June. Last year, 35 recycling facilities used AMP Robotics, says AMP spokesman Chris Wirth; by the end of 2020, nearly 100 will.

RDS Virginia, a recycling company in Virginia, purchased four AMP robots in 2019 for its Roanoke facility, deploying them on assembly lines to ensure the paper and plastic streams were free of misplaced materials. The robots could work around the clock, didn’t take bathroom breaks and didn’t require safety training, says Joe Benedetto, the company’s president. When the coronavirus hit, robots took over quality control as humans were pulled off assembly lines and given tasks that kept them at a safe distance from one another. Benedetto breathes easier knowing he won’t have to raise the robots’ pay to meet the minimum wage. He’s already thinking about where else he can deploy them. “There are a few reasons I prefer machinery,” Benedetto says. “For one thing, as long as you maintain it, it’s there every day to work.”

Companies deploying automation and AI say the technology allows them to create new jobs. But the number of new jobs is often minuscule compared with the number of jobs lost. LivePerson, which designs conversational software, could enable a company to take a 1,000-person call center and run it with 100 people plus chatbots, says CEO Rob LoCascio. A bot can respond to 10,000 queries in an hour, LoCascio says; an efficient call-center rep can answer six.

LivePerson saw a fourfold increase in demand in March as companies closed call centers, LoCascio says. “What happened was the contact-center representatives went home, and a lot of them can’t work from home,” he says.

Some surprising businesses are embracing automation. David’s Bridal, which sells wedding gowns and other formal wear in about 300 stores across North America and the U.K., set up a chatbot called Zoey through LivePerson last year. When the pandemic forced David’s Bridal to close its stores, Zoey helped manage customer inquiries flooding the company’s call centers, says Holly Carroll, vice president of the customer-service and contact center. Without a bot, “we would have been dead in the water,” Carroll says.

David’s Bridal now spends 35% less on call centers and can handle three times more messages through its chatbot than it can through voice or email. (Zoey may be cheaper than a human, but it is not infallible. Via text, Zoey promised to connect me to a virtual stylist, but I never heard back from it or the company.)

Many organizations will likely look to technology as they face budget cuts and need to reduce staff. “I don’t see us going back to the staffing levels we were at prior to COVID,” says Brian Pokorny, the director of information technologies for Otsego County in New York State, who has cut 10% of his staff because of pandemic-related budget issues. “So we need to look at things like AI to streamline government services and make us more efficient.”

Pokorny used a free trial from IBM’s Watson Assistant early in the pandemic and set up an AI-powered web chat to answer questions from the public, like whether the National Baseball Hall of Fame in Cooperstown, the county seat, had reopened. (It had, as of June 26, with limited capacity.) Now, Watson can answer 75% of the questions people ask, and Otsego County has started paying for the service, which Pokorny says costs “pennies” per conversation. Though the county now uses AI just for online chats, it plans to deploy a Watson virtual assistant that can answer phone calls. Around 36 states have deployed chatbots to respond to questions about the pandemic and available government services, according to the National Association of State Chief Information Officers.

IBM and LivePerson say that by creating AI, they’re freeing up humans to do more sophisticated tasks. Companies that contract with LivePerson still need “bot builders” to help teach the AI how to answer questions, and call-center agents see their pay increase by about 15% when they become bot builders, LoCascio says. “We can look at it like there’s going to be this massive job loss, or we can look at it that people get moved into different places and positions in the world to better their lives,” LoCascio says.

But companies will need far fewer bot builders than call-center agents, and mobility is not always an option, especially for workers without college degrees or whose employers do not offer retraining. Non-union workers are especially vulnerable. Larry Collins and his colleagues, represented by SEIU Local 1000, were fortunate: they’re being paid their full salaries for the foreseeable future in exchange for taking 32 hours a week of online classes in computer skills, accounting, entrepreneurship and other fields. (Some might even get their jobs back, albeit temporarily, as the state upgrades its systems.) But just 11.6 % of American workers were represented by a union in 2019.

Yvonne R. Walker, the union president, says most non-union workers don’t get this kind of assistance. “Companies out there don’t provide employee training and upskilling–they don’t see it as a good investment,” Walker says. “Unless workers have a union thinking about these things, the workers get left behind.”

In Sweden, employers pay into private funds that help workers get retrained; Singapore’s SkillsFuture program reimburses citizens up to 500 Singapore dollars (about $362 in U.S. currency) for approved retraining courses. But in the U.S., the most robust retraining programs are for workers whose jobs are sent overseas or otherwise lost because of trade issues. A few states have started promising to pay community-college tuition for adult learners who seek retraining; the Tennessee Reconnect program pays for adults over 25 without college degrees to get certificates, associate’s degrees and technical diplomas. But a similar program in Michigan is in jeopardy as states struggle with budget issues, says Michelle Miller-Adams, a researcher at the W.E. Upjohn Institute for Employment Research.

House and Senate Democrats introduced a $15 billion workforce-retraining bill in early May, but it hasn’t gained much traction with Republicans, who prefer to encourage retraining by giving tax credits. The federal funds that exist come with restrictions. Pell Grants, which help low-income students pay for education, can’t be used for nontraditional programs like boot camps or a 170-hour EMT certification. Local jobless centers, which receive federal funds, spend an average of $3,500 per person on retraining, but they usually run out of money early in a calendar year because of limited funding, says Ayobami Olugbemiga, press secretary at the National Skills Coalition.

Even if federal funding were widely available, the surge of people who need retraining would be more than universities can handle, says Gabe Dalporto, the CEO of Udacity, which offers online courses in programming, data science, AI and more. “A billion people will lose their jobs over the next 10 years due to AI, and if anything, COVID has accelerated that by about nine years,” says Dalporto. “If you tried to reskill a billion people in the university system, you would break the university system.”

Dalporto says the coronavirus should be a wake-up call for the federal government to rethink how it funds education. “We have this model where we want to dump huge amounts of capital into very slow, noncareer-specific education,” Dalporto says. “If you just repurposed 10% of that, you could retrain 3 million people in about six months.”

Online education providers say they can provide retraining and upskilling on workers’ own timelines, and for less money than traditional schools. Coursera offers six-month courses for $39 to $79 a month that provide students with certifications needed for a variety of jobs, says CEO Jeff Maggioncalda. Once they’ve landed a job, they can then pursue a college degree online, he says. “This idea that you get job skills first, get the job, then get your college degree online while you’re working, I think for a lot of people will be more economically effective,” he says. In April, Coursera launched a Workforce Recovery Initiative that allows the unemployed in some states and other countries, including Colombia and Singapore, to learn for free until the end of the year.

Online learning providers can offer relatively inexpensive upskilling options because they don’t have guidance counselors, classrooms and other features of brick-and-mortar schools. But there could be more of a role for employers to provide those support systems going forward. Dalporto, who calls the wave of automation during COVID-19 “our economic Pearl Harbor,” argues that the government should provide a tax credit of $2,500 per upskilled worker to companies that provide retraining. He also suggests that company severance packages include $1,500 in retraining credits.

Some employers are turning to Guild Education, which works with employers to subsidize upskilling. A program it launched in May lets companies pay a fee to have Guild assist laid-off workers in finding new jobs. Employers see this as a way to create loyalty among these former employees, says Rachel Carlson, the CEO of Guild. “The most thoughtful consumer companies say, Employee for now, customer for life,” she says.

With the economy 30 million jobs short of what it had before the pandemic, though, workers and employers may not see much use in training for jobs that may not be available for months or even years. And not every worker is interested in studying data science, cloud computing or artificial intelligence.

But those who have found a way to move from dying fields to in-demand jobs are likely to do better. A few years ago, Tristen Alexander was a call-center rep at a Georgia power company when he took a six-month online course to earn a Google IT Support Professional Certificate. A Google scholarship covered the cost for Alexander, who has no college degree and was supporting his wife and two kids on about $38,000 a year. Alexander credits his certificate with helping him win a promotion and says he now earns more than $70,000 annually. What’s more, the promotion has given him a sense of job security. “I just think there’s a great need for everyone to learn something technical,” he tells me.

Of course, Alexander knows that technology may significantly change his job in the next decade, so he’s already planning his next step. By 2021, he wants to master the skill of testing computer systems to spot vulnerabilities to hackers and gain a certificate in that practice, known as penetration testing. It will all but guarantee him a job, he says, working alongside the technology that’s changing the world.

–With reporting by Alejandro de la Garza and Julia Zorthian/New York

No comments:

Post a Comment